The new A-Series, which was launched in August 2019, is ExTe’s third generation of aluminium bunks, and is by far the lightest on the market. The A-Series was designed to meet the demands for extremely light timber bunks, making it possible to load more timber and improve profitability for the hauliers.

The new A-Series is lighter than its predecessors. By combining the different A-bunks based on your transportation conditions, you can increase the payloads. This means better profitability.

The A-bunks are available in the following performance stages:

A5 - maximum load per bunk: 5 tonnes

A7 - maximum load per bunk: 7 tonnes

A10 - maximum load per bunk: 10 tonnes

A number of different fastenings are available for the A-Series, including clamp fastenings, friction fastenings and reel fastenings. Another option is pre-fitted fastenings, installed in the factory.

The stanchions are locked into place with a tapered clasp, which is treated with a low friction coating. Together with ExTe’s modular system, assembling and switching stanchions is therefore both quick and simple.

Tailored to your transportation needs

If you have the right combination of the new A-bunks you can save up to 220 kg compared to the predecessor, thereby make a significant contribution to profitability.

Functional design with stabilising flange

The design focuses on the low weight of the A-Series. The specially treated surface makes the bunks easy to keep clean and look good over a long period.

The bolster has a built-in flange to ensure the stability of the bunk. The flange has also been pre-drilled for the installation of various accessories, such as tensioners.

100% aluminium and prepared for accessories

The bolsters, stanchions and fastenings are all made entirely from aluminium, and have been designed for the demanding Nordic conditions.

The flanges on the bolsters are pre-drilled for simple installation of accessories, such as TU tensioners. The pre-drilled holes are the same on both sides of the bolsters, allowing flexible assembly.

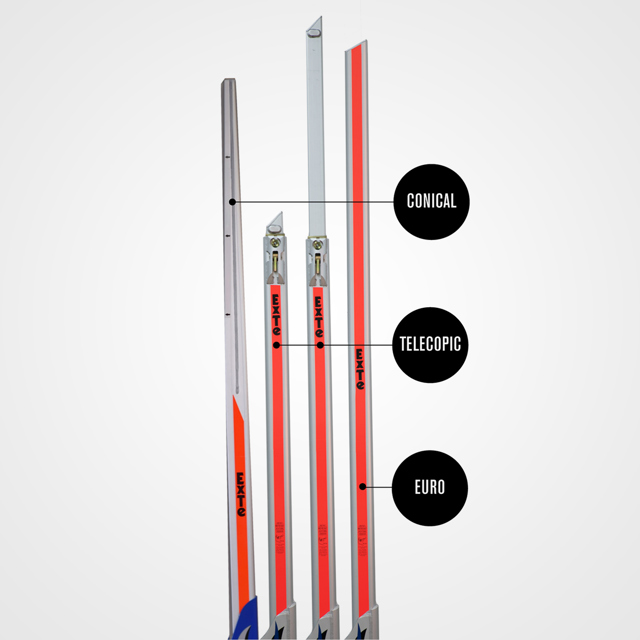

New stanchions have been developed for the new A-Series.

The design is both lighter and stronger. The same stanchions now fit both the A- and D-series. This also applies to Telescopic stanchions.

The stanchions are available for various load heights, and the stanchions for the older A-Series will remain available as spare parts.

Telescopic: Stanchions with a freely adjustable upper part

Conical: Stanchions that are bevelled on both inside and outside

Euro: Full profile without telescopic function or bevelling