The 144 system is predominantly built in high tensile steel and includes a product mix that is ideal for hauliers who do not just transport roundwood.

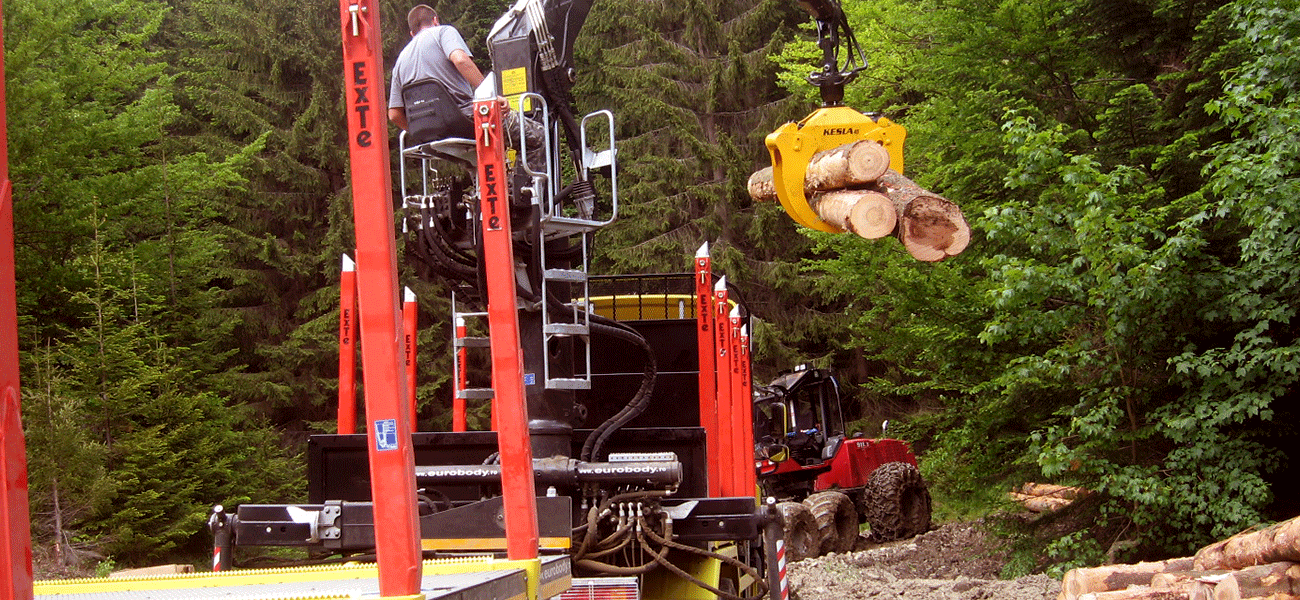

ExTe’s all-time best-selling bunks. The powerful and sturdy system is reliable, versatile and easy to transfer to the next rig when it is time to switch. That is why System 144 is so popular among hauliers all over the world.

System 144 can withstand extreme pressure for a long period of time. The upper section of the telescopic stakes is aluminium. The interaction between the stakes, bolsters and bolster attachments makes the overall structure resilient to any possible handling miscalculations during loading and offloading.

System 144 is available in the following performances:

144 - Max. load per bunk: 7 tons. Weight from 130 kg.

144-S - Max. load per bunk: 7 tons. Weight from 130 kg.

The interaction between the stakes, bolsters and bolster attachments makes the overall structure resilient to any possible handling miscalculations during loading and offloading.

Flatbed sockets increase the options. Even the flatbed sockets are made from high tensile steel. The sockets are heat-treated and suitable for welding, without the need for preheating. Sockets are usually fitted to flatbed configurations, which have been designed for mixed cargo.

Lightweight, practical welding attachments

The bolster attachments are made of steel and are vital components of major significance for the service life and roadworthiness of thex equipment. The attachments are also important for the flexibility of the bolsters. The lightweight, practical welding attachments come sand-blasted. They are available in various designs, including clamp, friction and roller attachments

Stake attachment options

Stakes can be attached using bolt connectors or quick release locking. Both options are compatible with all 144 bolster and sockets. Bolt connectors are recommended for more permanently positioned stake.

Bolt-mounted bracket attachments provide flexibility without the need for welding

Bracket attachments enable the bolster to be attached to any bolster width. During assembly, holes are drilled into the side of the bolster and the mount is bolted on. Bracket attachments are supplied coated. They are available in various designs, including clamp, friction and roller attachments.

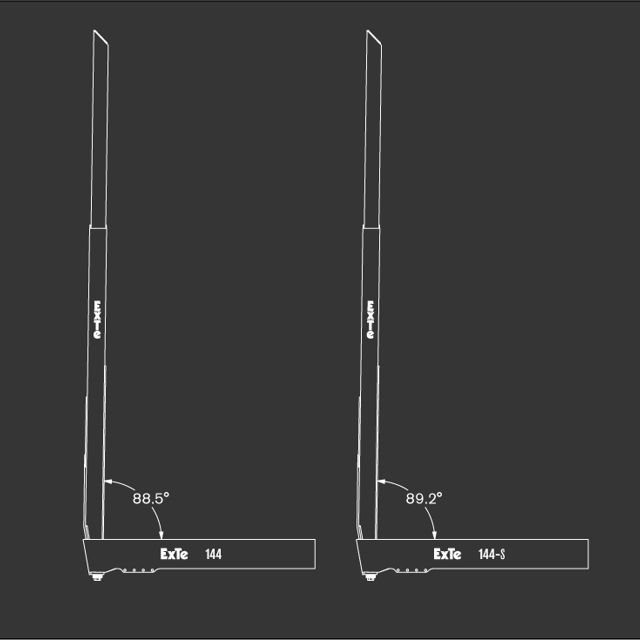

Bolsters in 2 varianter: 144 and 144-S

The bolsters are made of steel. The difference between the bolsters is that 144-S gives less inward inclination, 89.2 °, on the stakes and thus greater width between the tops. An advantage when loading dimensionally stable goods such as sawn wood products. The standard 144 bolster gives a slightly larger inward inclination, 88.5 °, on the stakes and is therefore excellent for transporting round timber.

The bolsters can, depending on the customer's wishes, be equipped with extra flat sockets recessed in the bolsters.

Bolsters with center sleeve are available as standard. Bank bolsters can advantageously be built in as load-bearing elements in the flat construction.

Flatbed sockets

The flatbed sockets, which weigh 7.1 kg, are heat-treated and well adapted for welding. The sockets are usually mounted in flatbed constructions, which are intended for mixed goods. If the transports will mainly consist of round timber, it is recommended that the sockets be mounted so that the stakes have an inward inclination of 1.5 °, so that the load profile is not exceeded. When welding sockets, it is a requirement that the welding can withstand a torque of at least 6 ton meters. Any reinforcements in the platform and bolsters must be individually adapted to the location of the sockets and the other conditions of the platform. The responsibility for achieving the strength of the sockets rests with the person who does the assembly / welding.

Stake assembly

The stakes can be mounted either with bolted joints or quick locks. Both options fit in all banking bolsters and flatbed sockets. Bolt joints are recommended in cases where the stakes are to have a more permanent placement. The bolt joint consists of, in addition to a high-strength screw with a nut, five disc springs whose task is to keep the joint elastic and properly tensioned, without straining strength limits. An ingenious technology that multiplies the life of the bandage.

Quick lock is the option, which allows the fastest and easiest movement of the stakes. They are locked with a special control key. The locking mechanism is built according to the eccentric principle. In the locked position, a compression spring is compressed, the force of which is released when the lock is opened.

Load capacity: 7 tons

Weight (bolster): from 85 kg (2500 mm width)

The brackets are made of steel. The flat sockets are heat-treated and well adapted for welding, without the need for preheating. The sockets are usually mounted in flat constructions, which are intended for mixed goods.

The lower profile of the telescopic stake, as well as the euro stake, is powder coated. The upper profile of the telescopic roof of aluminum is anodised.

Bolsters 144 and 144-S can be equipped with extra stack sockets recessed in the bolsters. Bolsters with center sleeve are available as standard.